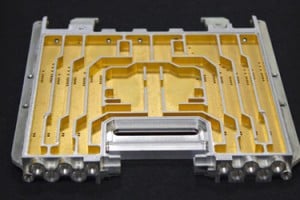

Being an industry leader in gold plating in Massachusetts and around the country means being able to educate all new and returning customers on the different services we offer. One of many includes our gold plating for all applications with specialties in the aerospace, telecommunications, optical and electronic, and medical industries. Gold is commonly used because of its increased functionality, practicality, and effectiveness of its applications. There are various grades and types of gold plating, including grade D.

What is grade D gold plating?

The grade of gold plating follows the Knoop hardness test which was developed by Frederick Knoop and his National Bureau of Standard’s colleagues in 1939 defined by the ASTEM E384 standard. There are four grades: A, B, C, and D. Variables such as environment, temperature, and load can have impacts on testing and are taken into consideration during the examination.

Specifically, Grade D gold plating has a 201 Knoop and over. The Knoop hardness test examines the hardness of more fragile materials or thin sheets. Knoop values usually range from 100-1000 and is an ideal test to understand the limitations of a product on a small sample of material. This hardness allows gold to not only provide its typical corrosion and wear resistance but also can provide the level of stability necessary for the industry and product being made.

It’s best to work with a business who specializes in your field, understands your needs, and can provide the best quality gold plating possible. At AOTCO, we will plate to your specified coating requirements. As grade D gold platers, we can create products that comply with the requirements of various industries to ensure a flawless product. Our quality control management system is designed to exceed the expectations of our customers.

With more questions, please contact our experts today at (888) 275-0880.